Apprentices and Trainees

Along with other large engineering companies in the post-war boom years, Associated Motor Cycles Ltd ran an apprenticeship / trainee scheme that, due to its unrivalled in-house manufacturing facility, offered school-leavers a chance to gain worthwhile experience in several different trades.

Not only did the scheme allow AMC to maintain it's own skill base, but it helped to cross-fertilise similar firms in the same sphere of work with a supply of young qualified staff.

Being accepted to work in a firm producing high-powered motor cycles gave great kudos to a teenage lad, but this quickly wore off when he realised that his meagre take-home pay on a Friday (after deductions for Mum and petrol) didn't leave much for a round at the pub with his higher-earning ex-school mates.

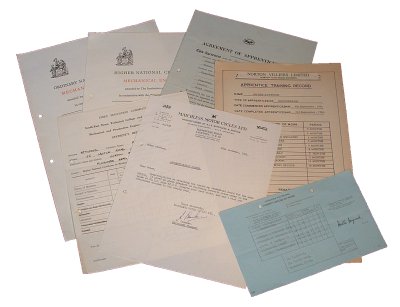

The apprentice intake took place each September, usually four in number, and they would have signed an agreement to remain with the company for a five year term.

During this time, each would spend time in the main departments for periods ranging from two months to a year, with one day a week college release provided to hopefully achieve Ordinary and Higher National Certification (or equivalent).

.jpg)

.jpg)

.jpg)

The core factory workshops that all apprentices would take turns working in were: Drilling, Milling, Grinding, Capstans, Gearcutting, Heat Treatment, Inspection and Assembly.

Assuming adequate progress was made in these areas, There was also the opportunity to spend time in some of the other, more technically demanding areas of the firm, such as the Race Shop, Tool Room and Metallurgy Department.

Time in some areas, such as the Finishing and Welding shops, was not included in the training scheme on the grounds of safety, although, in the case of the Finishing Department, the true reason might have been to curb the desire to have the most highly polished, plated and painted bike in the firm!!

[However, a resorceful apprentice would always have cultivated a collection of useful contacts during his placements throughout the firm which, when the need arose, could be relied on to help out. Bob Cakebread relates the workings of this fine tradition in his story One Piece at a Time.]

After the first four years of gaining experience of the working practices throughout the firm, both the management and the apprentice would have a fair idea of the most suitable department for eventual specialisation.

The final year of the apprenticeship would then be spent in this chosen area, working alongside its staff and learning from them all that is needed to carry out the work involved, to an increasing level of competence.

.jpg)

For many, this final year would be spent in the Tool Room where they would be taught how to produce the accurate jigs, fixtures and gauges needed throughout the firm, whilst others would learn how to design these components and plan for their use in the Tool Design Office.

A high proportion of apprentices would end their training in the Drawing Office, where their previous years' workshop experience would prove to be invaluable. They would have the practical knowledge behind them to enable the design of components that were not only functional, but also fitted in with the invariably specialised production methods used throughout the factory.

As well as end of year reports from the college, each department manager at the firm was required to give comments on his apprentice's performance to the personnel manager, and these reports were used by the management in deciding the awards for practical and academic achievement, handed out at a special ceremony attended by parents each December.

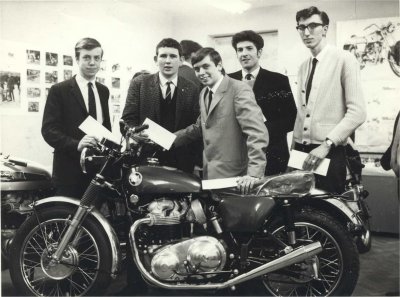

From time to time trips would also be arranged to take groups of apprentices to other firms in the area, such as the Woolwich Arsenal, Ford Motors in Dagenham, and the Stones foundry in Charlton (where the aluminium castings for AMC were produced).

These specially arranged visits comprised guided tours of the companies, giving the chance to see how work in other fields of engineering was set up and operated.

The foundry visit was especially valuable to the AMC apprentices as this important, and interesting, activity was one of the few that was not carried out in-house at Plumstead.

In tandem with the apprenticeship scheme, trainees (or craft apprentices) were also taken on to serve a three year term, with more emphasis on achieving proficiency in the manual skills needed in specialist departments such as the tool room.

Some of the above pictures are taken from an article on the AMC apprentice scheme, entitled 'Making Motorcycles', that was published by the Motor Cycle newspaper in their 1966 special First Gear supplement.

Click button for more 'out of overalls' apprentice pictures.

| James Akers | ||

| Les Apps | 1962 - 67 | Remained in Drawing Office to 1969 |

| Peter Attwood | 1961 - 66 | Remained in Drawing Office to 1969 |

| Dennis Boney | 1955 - 60 | Remained in Tool Room to 1961 |

| Michael Bonner | ||

| Brian Bonner | ||

| Barry Buckingham | ||

| Bill Cakebread | 1958 - 63 | Remained in Drawing Office to 1966 |

| Bob Cakebread | 1962 - 67 | Remained in Drawing Office to 1969 |

| Malcolm Cook | 1962 - 66 | Left due to timekeeping |

| Bernard Copleston | ||

| Alan Crouch | 1958 - 63 | Remained in Tool Room |

| Roy Cunningham | 1960 - 65 | Remained in Tool Room (jig borer) to 1966 (then to Fords) |

| Trevor Denman | 1959 - 64 | Remained in Drawing Office to 1969 |

| Derek Dixon | ||

| Roger Dulake | 1962 - 64 | Dismissed |

| Douglas Dunwoody | ||

| Bill Ellis | ||

| John Foster | ||

| Chris Garbaro | 1961 - | Died |

| Mick Giddings | 1957 - 62 | Remained in Tool Design |

| Chris Grace | 1962 - 67 | Remained in Drawing Office to 1969 |

| Peter (Fluff) Guinigault | Remained in Tool Cutter Grinders | |

| Edward (Ned) Hooker | Remained in Drawing Office to 1968 ? | |

| Mark Hosken | ||

| Keith (Ginger) Jackson | 1961 - 66 | Joined Fords at research centre |

| Derek Lloyd | ||

| Ron Melrose | ||

| Fred Miles | 1959 - 64 | |

| Mick Odell | 1956 - 61 | Remained in Tool Design to 1961 |

| Alan Puplett | 1965 - 69 | |

| Barry Rennick | ||

| Dave Smith | 1961 - 66 | Joined fire service |

| Mickey Thorne | ||

| Alan Varney | ||

| John Wallace | H Collier & Sons | |

| Terry Wetherfield | Remained in Drawing Office to 1969 | |

| Ken Whincop | ||

| Derek Munton | Remained in Press Tool / Planning |

| Tony Botting | Remained as a Tester | |

| Bob Chandler | 1962 - 65 | |

| Norman Crew | Remained in Millwrights | |

| Roy Gilbert | ||

| John Kelleher | 1958 - 61 | Remained in Sub-Contracts |

| Ray Lightfoot | 1959 - | Remained as a Tester |

.jpg)