Spares, Repairs and Service

.jpg)

Spares

Although well built and reliable as the bikes from the Plumstead Road factory undoubtedly were, there would still come a time for every owner to use the facilities provided by the Spares and Service Departments of AMC.

For those who lived local to Woolwich, this would have meant a visit to the buildings that were situated on the opposite side of Burrage Grove to the factory, behind whose counters the experienced staff would (hopefully) be able to locate and supply the parts needed to get your motorcycle back into running condition.

The far end of the building, adjacent to the Race Shop, housed the Spares Department with public access to it via double doors at the top of the long stone steps. The near end was occupied by the Service and Repair Department.

.jpg)

Others who lived further afield, or overseas, would be able to make use of the vast dealership network that had been built up over the years to obtain original manufactured spare parts that could be relied on as exact replacements for their bikes.

Coordinating this constant flow of parts from the factory's production departments to the many spares stockists was a daunting task that required close cooperation between the Spares Department and the progress controllers in the factory, whose other priority was to ensure that the production lines were keep supplied with parts for the new builds. In times of high demand for new machines, this was quite a balancing act.

.jpg)

.jpg)

It's worth remembering that all this coordination work between the dealers, the spares department and the factory took place in a pre-computer age.

All the operations inevitably involved paperwork, in the form of order requisitions, invoices (view sample here), receipts, etc., the recording of which would have been done on various card indexing systems that needed to be efficiently maintained to avoid problems.

The majority of staff employed in both the Spares and Service Departments would have been long serving employees whose experience and contacts were vital to make it run smoothly. It was a day-to-day challenge in trying to locate and despatch selected parts from the thousands of possibilities to all parts of the world.

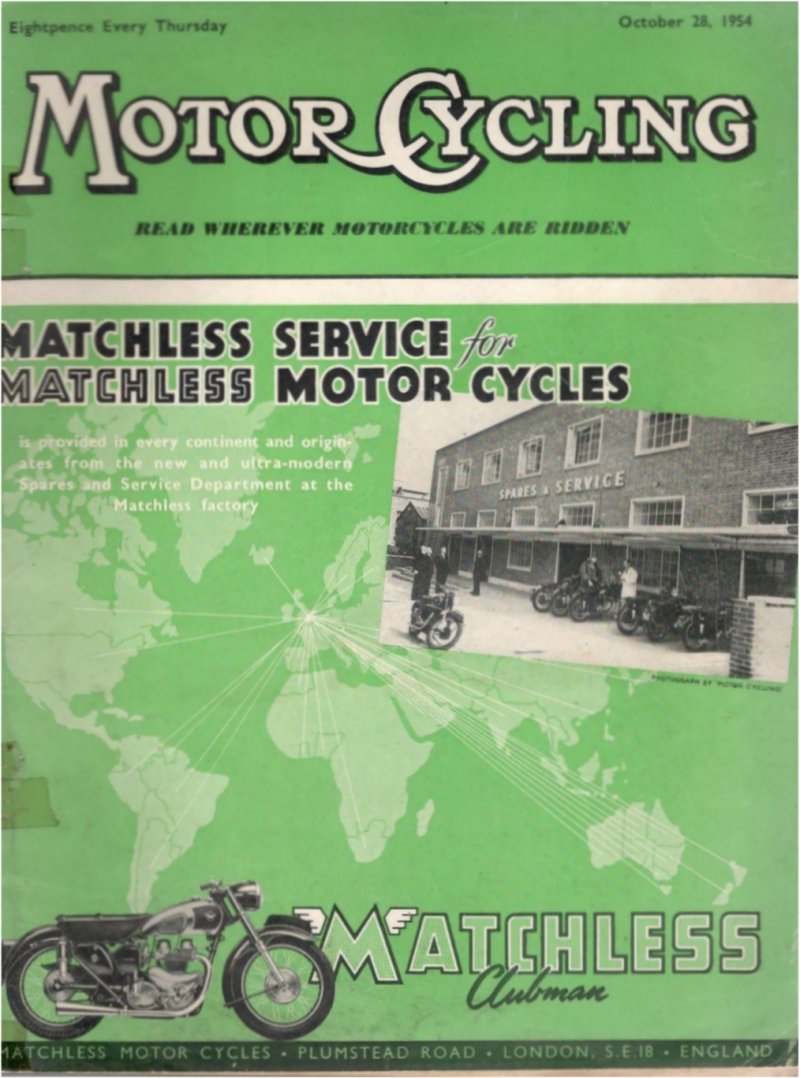

In the picture (right) of the Spares and Service building, bikes can be seen outside the service department just behind

the car parked on the pavement.

The site for the firm's intended further expansion can be seen beyond the service building.

Service and Repair

No matter how carefully you ride a motorcycle and how diligently your maintenance of the machine, unless you are

very fortunate, there will eventually come a time when serious service or repair work becomes necessary.

For anything that was beyond the capability of the owner, the Service Department could be relied on to come to the rescue.

.jpg)

.jpg)

With convenient access to the comprehensive stock of spare parts in the adjacent department and staffed by an experienced team who were familiar with every model of bike, past and present, that the Company had produced, there was little repair work that couldn't be undertaken.

Ex. experimental dept employee Dick Palmer was featured in this AMC 250 engine rebuild magazine article:

.jpg)

.jpg)

.jpg)

.jpg)

Being a motor cycle enthusiast yourself was also a bonus in dealing with customers, as was the case with the appointment of both ex-ISDT rider Hugh Viney and later Fred Neill to manage the Service Department.

.jpg)

(During the peak of his trials days, Hugh once practiced his technique by repeatedly climbing and descending one of the stone staircases from ground floor to the roof on his bike, until he could do a run without having to put a foot down).

You can download a short (60 sec) video clip of Hugh Viney, on his return from the 1954 ISDT event, discussing design modifications with Bob Manns in the Competition Shop and with one of the Design staff by clicking here.

Fred Neill was a long term employee and former tester whose encyclopaedic knowledge enabled him to compile the invaluable instruction books.

He was also the author of the much respected 'Practical Guide' books about the various model ranges of AMC motorcycles.

John Hudson was another uniquely dedicated employee who had moved down from Bracebridge Street when Norton production was relocated to Plumstead.

He was not only conversant with just about every component used on Norton machines but would do anything to solve a customer's problem. This would often involve riding hundreds of miles in all weathers at great personal discomfort and sacrifice to carry out a replacement or repair at the customer's home.

John was also unbelievably helpful to the AMC drawing office staff who had the task of assimilating many of the Norton parts into the AMC system and then into the various Matchless-framed/Norton-engined hybrid machines that were subsequently developed.

These Motor Cycling magazine cover page featured the Spares and Service department.

(Click on the image to see enlarged view)

You can view the complete collection on Cover Pages.

| Pearl Carmen | Secretary | |

| Jack Checkley | Manager | |

| Bob Day | ||

| Jeanette Farley | Typist | |

| Violet Huckfield | Supervisor (invoicing) | |

| Emily Leonard | Office Clerk | |

| Fred Norman | Sales | |

| Mike Wicks | ||

| Ida Wilkinson | 1955 - 1964 | Audio Typist |

| Bill Wright | Sales |

| Ken Chale | ||

| Herbert Coomber | Assistant manager | |

| Reg Curley | ||

| John Hudson | Assistant Manager (ex. Norton) | |

| Arthur Lewthwaite | ||

| Jim (Mouldy) Molesworth Edwards | ||

| Fred Neill | Manager | |

| Ray Oliver | Engines (assistant to John Hudson) | |

| John Robarts | 1959 - 66 | Assistant Manager (AJS/M) |

| Sid Thompson | ||

| Hugh Viney | Manager | |

| Jim Walby | ex.testing | |

| Cyril Vernon (Vern) Wallis | 1950 - 53 | show stand |

| Graham Weeks | ||

| Derek Wickes | ||

| Elsie Woodley | Secretary to Fred Neill |

| Kenny Chater | ||

| Alf Curley | Forks | |

| Mick Duffy | ||

| Gerry Hartnell | Later Drawing Office clerk | |

| Ray Learton | ||

| Dick Palmer | Engines (ex. Experimental Dept) | |

| Ernie Thomas | Forks & suspension | |

| Frank Topps | ||

| Mike Wicks | Later Engine Shop |

.jpg)