Competition and Race Shop

Along with the Service/Spares and the Packing Departments, the AMC Competition and Race Shop (known simply as the Race Shop)

occupied a position on the opposite side of Burrage Grove to the main factory.

It was a long, single-storey building that stretched back to the local railway embankment.

Access to its narrow end, which faced the road, was via a door at the top of a short flight of steps, with another entry door

located further down on its left-hand side.

Although housed under the same roof, there was a very clear distiction between the two departments, each with their own manager

and dedicated personnel who were all highly-skilled, being either respected or envied by the rest of the factory workers.

Some saw them as the cream of the fitters and were proud of the company's involvement in racing. Others simply saw them as a

bunch of lazy jokers who had the spare time to play games, while they had to sweat it out on piece-work in order to take home

a sensible wage.

But, behind the scenes, the Race Shop staff not only had to exercise meticulous care in the necessarily slow building of a race

or competition bike, but also work all the unsociable hours imaginable when the pressure was on before a race like the Isle of

Man Tourist Trophy races or Six-day Trials event.

They did, however, have 'perks', and the riders were known to give treats to their supporting mechanics to ensure that they remained dedicated to the task. (It was not unknown to occasionally see a famous rider slip into the Race Shop via the back door laden with a crate of beer, and these events no doubt added to the feeling amongst many that it was not just the road that separated the Race Shop from the rest of the factory!)

The Competition Shop

.jpg)

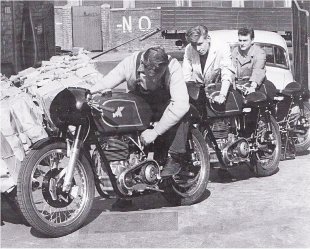

The road-end of the building was allocated to the Competition Department, comprising two fixed-height bike preparation benches where scrambles machines were built to the specific requirements of works riders such as Vic Eastwood, and separately managed by Wally Wyatt.

.jpg)

.jpg)

(You can view another photo of Wally Wyatt on the Scrapbook page.)

The Race Shop

The remainder of the building was under the control of development engineer Jack Williams who had his office at the rear (under a mezzanine floor where the race shop spares were stored), and looked out onto an engine assembly area, comprising assembly benches on one side with a lathe, cam profiling machine and various small machine tools along the other wall.

In the centre of the building, arranged at an angle, were several fixed-height bike building benches where the highly-skilled, specialist personnel took meticulous care in their preparation of 7R and G50 racing machines, often under pressure before major events, such as the Isle of Man TT races.

.jpg)

.jpg)

.jpg)

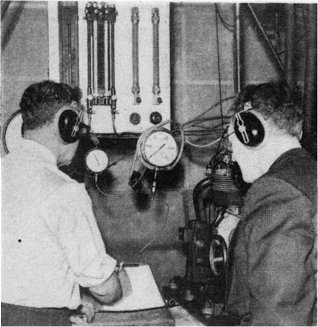

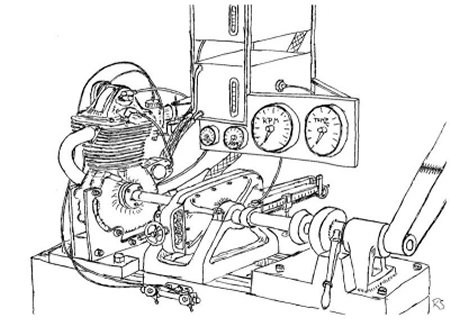

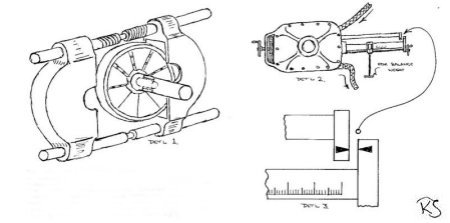

Outside, beyond the rear wall of the race shop, two water dynamometers were housed in separate underground caverns, accessed by steep steel ladders, where engines were tested for power output behind steel mesh guards.

Large diameter 2-speed fans, drawing in air from the roof, were positioned in front and behind the open-exhaust engine to provide air cooling at speeds up to 95 mph.

Readings were taken by the (well-earmuffed) testers of the brake output, speed, fuel consumption, barometric pressure, etc.

Note: Winter was not always the best time for testing as, if it was snowing outside, the fans would blow snow onto the test bed.

Fortunately, the exhaust noise from the test pits exited onto a railway line and not near to any housing, or the race shop would have received quite a few complaints from otherwise fairly tolerant neighbours.

In 1962, the Dutch Motor magazine published a series of articles following a tour of the Plumstead Road factory.

You can read their detailed observation of the Race Shop in Part 4 of

'This is How Your AJS and Matchless is made'.

.jpg)

Keith Jackson recalls that, during his apprenticeship placement in the race shop, in mid-1963, he was chosen to help out with a special engine test on the dynamometer.

It appears that the company had allowed Paul Dunstall (who had close contacts with AMC) a day's grace on the main test bed to try to improve the power output of one of his Domiracer engines.

Keith says that 'I had to install his engine onto the test bed, couple it up and then work with Jack Williams and Paul Dunstall

to run the power curves on the dyno.

The work that day was mostly assisting when running the dyno, then having to extend the engine inlet tract with spacers,

shorten the exhaust pipes and then run another power curve.

This was done many times over that day and the engine power output was improved'.

Sadly, Keith can't remember just what the power output was after all the changes, but refers to his contribution in obtaining it as 'such a privilege to have been involved in that day'.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

The original versions of the 1951 Isle of Man group photos, with captions by Paul Packman, can also be viewed on the Scrapbook page..

(see also names highlighted in the personnel list for their Cover Page stories)

.jpg)

It took a toss of a coin to decide whether this picture should be placed on the Race Shop or Packing page, as it had certain merits for either.

It's a rare picture of a porcupine racing bike being manhandled up the passenger steps of a plane by airport loading staff in September 1954.

Research has identified that it was outbound for a late-season meeting in South Africa.

Accompanying the bike on the flight were AMC race shop technician Jim Boughen and rider Rod Coleman (who were not allowed to perform the loading due

to airport security reasons.)

.jpg)

This Motor Cycle magazine cover page featured personnel of the experimental department.

(Click on the image to see enlarged view)

You can view the complete collection on Cover Pages.

| Jim Barratt | ||

| Stan Bassett | later tool room extension | |

| Jim Boughen | 1932 - 1969 | |

| Jack Brett | ||

| Bill Brooker | 1967 - | Comp Shop - mileage tester |

| Arthur Childs | engine builder | |

| Freddie Clarke | 1946 - 48 | Manager ex Triumph/Ariel |

| Joe Craig | 1941 - 46 | Manager ex Norton |

| Jack (JH) Colver | experimental/engine repair | |

| Jack Emmott | ||

| Eric Goodfellow | formerly tool room | |

| Wilf Graham | later tool room extension | |

| Henry John (Ike) Hatch | 1948-54 | 7R3 develoment engineer (d. 1954) |

| Des Henry | 1953 - ? | ex. HWM |

| Ted Iffland | 7R3 | |

| Phil Irving | Development engineer | |

| Bert Lambert | Wheel builder (comp shop) | |

| Arthur Keeler | engine builder | |

| Bill Lovett | 1919 - 48 | Porcupine engines |

| Reg Mason | engine builder | |

| Charlie (Ginger) Matthews | 1928 - ? | later drawing office clerk |

| Norman Maurice | ||

| John McLaren | 1950-69 | competition shop |

| Tommy Mortimer | machinist/engine builder (formerly tool room) | |

| Peter Murphy | ||

| Paul Packman | c. 1951 | |

| George Rowley | ex-AJS | |

| Monty Sayer | c.1953? | Manager |

| Bert Shade | ||

| Brian Spalding | ||

| Jack (C J) Williams | 1954 - ? | Manager/Dev. Eng. ex. Vincent |

| Matt Wright | Manager/Development Engineer | |

| Wally Wyatt | ? - 1969 | Competition Shop manager |

| Fred Wynn | 1941-1959+ | Development assistant |

.jpg)