Tool Design

The Tool Design department formed the link between the Drawing Office and the Tool Room, inasmuch as the planning work involved in taking a component from drawing board to assembly shop was carried out here.

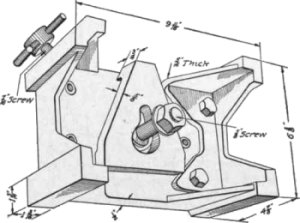

Even a relatively simple operation like drilling a hole in a cast or forged component would require some form of

fixture to hold the part in its correct orientation with sufficient accuracy, whilst accommodating the inherent tolerances

of the raw part.

This could entail the use of box jigs (as shown) that would incorporate various location features, hinged sections,

clamps and slip bushes, all of which would need careful thought in their design.

Whether or not a part needed jigs and fixtures in its manufacture, there would always be the need for gauges to be allocated in order that the required tolerances could be held when machined.

Located on the ground floor, on either side of the gangway that ran down to the canteen, between the Grinding Bay and the Heat Treatment shop, were two separate offices. The RH one, occupied by about four tool designers, a clerk and supervised by the office manager, was engaged on general tool and gauge design whilst the LH one was concentrated solely on press tool work.

.jpg)

Frequent interaction between the tool designer and the drawing office was usually necessary, during the planning stage,

to ensure that the cost of production was kept down to the minimum.

This would sometimes entail partial redesign of the component until it was satisfactory for all parties.

Once finalised, any tooling needed would be drawn up and passed to the Tool Room for manufacture.

| Mick Giddings | 1962 - 65 | ex. apprentice |

| Jim Hart | press tool design | |

| Len Morgan | ? - 1969 | Manager |

| Bill Murrow | ? - 1969 | Clerk |

| Mick Odell | - 61 | ex. apprentice |

| Albert Packman | 1927 - 1951 | press tool design manager |

| Harry Porter | ? - 1969 | |

| Jim Probert | ||

| Len Taylor | ||

| Mickey Thorne | ex. apprentice | |

| Archibald L A Timberlake | ? - 1926 |

.jpg)