Presswork

The AMC press shop was located on the ground floor of the factory, between the Milling and Grinding bays.

The area that all three of these bays occupied was a single storey extension that spread into the centre of the main U-shaped factory.

The floor to ceiling height was quite sufficient for the original press shop machinery but, when a 300-ton press was to be installed, a tower had to be built around it because it poked up through the roof!

Having such a massive machine operating in close proximity to the grinding bay didn't do much good to the finishes and accuracy needed on the latter's work.

(It was stated that, at one time, the vibrations from the monster press were causing the grinding machines to move on their bases, some by several inches, before it was realised that the subsoil under the factory was just white silver sand)

.jpg)

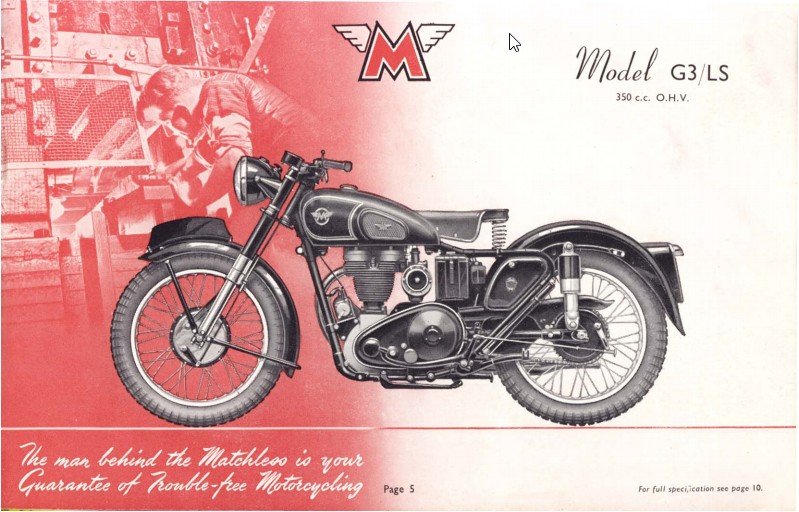

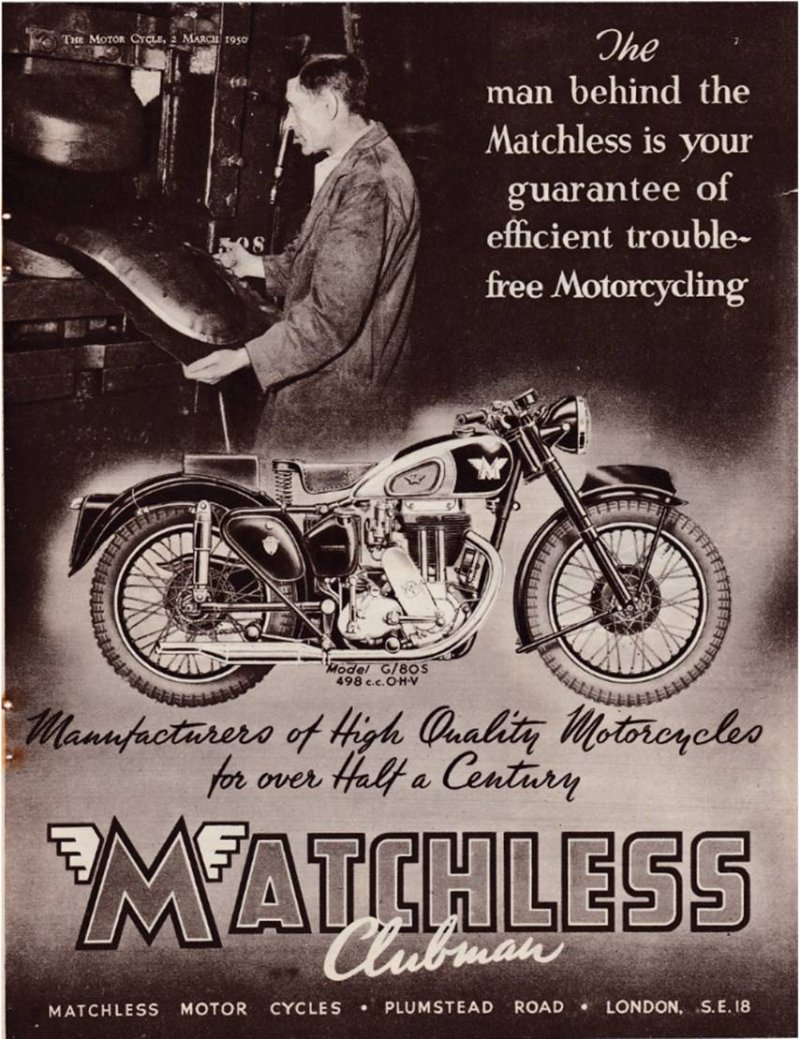

The work carried out in the Press Shop varied from the largest petrol tank components (shown here) to many more smaller, hidden items, like frame brackets and spanner sets.

This sales brochure and poster featured work carried out in the presswork department.

(Click on the images to see enlarged views)

You can view the complete collection on Cover Pages.

| Richard Andrews |

.jpg)